SWENext Tips: How to Apply for SWE Scholarships

Calling all high school seniors! Scholarship application season is here.

Read moreSign up for the monthly All Together newsletter

Recent Diversity & Inclusion

Recent Videos

Recent SWE News

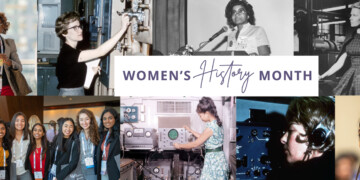

SWE and NIHF Museum Partner on Women’s History Month Exhibit

This new exhibit, located in Alexandria, Va., highlights the achievements of six women leaders in STEM who are breaking boundaries...

Celebrate Women’s History Month With SWE

Join the Society of Women Engineers (SWE) in commemorating Women's History Month with a collection of podcasts, blogs and magazine...