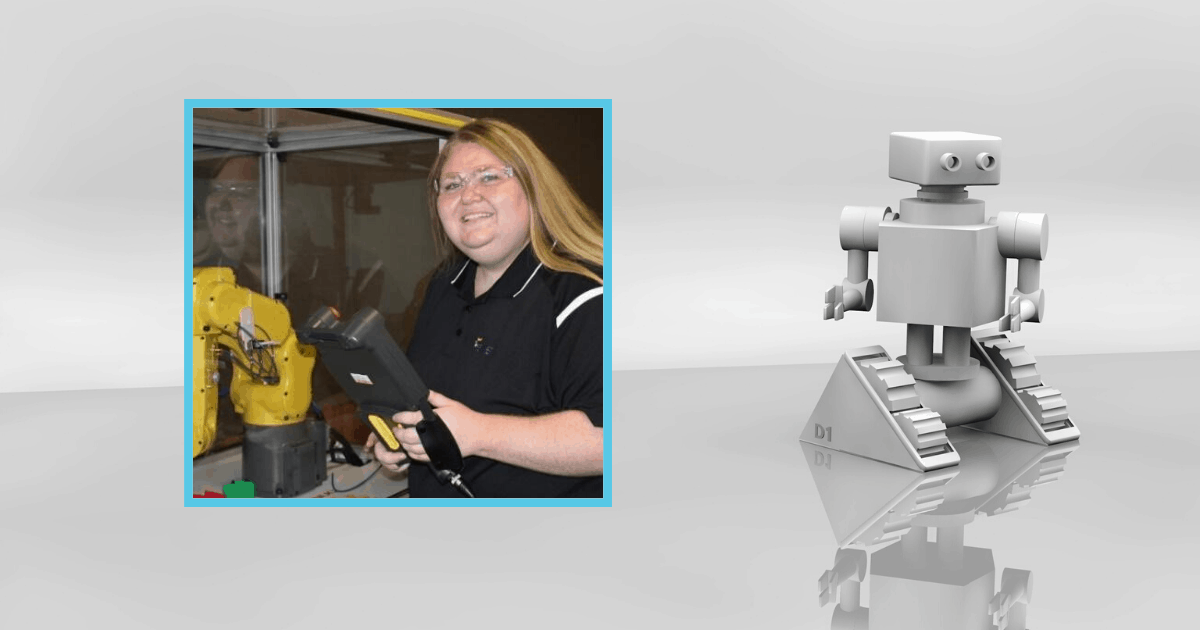

In my freshman year of high school, I went to a Women in Technology camp. We got exposure to a variety of engineering disciplines like Mechanical, Electrical, and Computer Engineering. Then, we got to do robotics! We got to use industrial robots that are used in factories around the world. I fell in love and decided I wanted to be a Robotics Engineer.

In my freshman year of high school, I went to a Women in Technology camp. We got exposure to a variety of engineering disciplines like Mechanical, Electrical, and Computer Engineering. Then, we got to do robotics! We got to use industrial robots that are used in factories around the world. I fell in love and decided I wanted to be a Robotics Engineer.

I got my Mechanical Engineering degree with the Robotics option at Lake Superior State University in addition to an associate’s degree in Computer Science. I had two internships when I was in college. During both, I got to work with robots, which solidified my career interest. For one internship, I installed two robots and helped debug the system. For the other internship, I worked with the same robot type at a sealant company. I was able to do different lab tests and make videos for buyers. The videos showed different equipment types and capabilities so buyers knew what the products could do for their company.

After I graduated and worked for a couple of years, I got my master’s degree in Integrated Manufacturing Systems Engineering from North Carolina State University. In other words, I studied combined mechanical and electrical systems in a manufacturing environment.

Recently, I transferred to our Corning Life Sciences facility in Durham, North Carolina. I’m a Senior Controls Engineer, which you’ll notice is not what I went to school for. I work on projects that support the plant and assist in maintaining the operations of the facility. We’re one of the lines of defense if a machine goes down to make sure our products get out the door and get into the hands of our customers. Most of what we do is project work. We try to optimize the equipment, reduce costs needed to run the machines, limit the amount of scrap produced by the process, and assess new equipment coming in for a new project or product. I love that I get to work on products that people use in their everyday lives, such as glass for LCD TVs, glass on your phone or glass products used in labs.

One type of Robotics Engineering is like what you see in FIRST, where the robots learn their environment and what paths to take. However, I work primarily with industrial robot arms, which is a whole other area of robotics. Some can lift up an entire car body. Some are small enough to sit on a tabletop. There are opportunities both in the design and the implementation of these robots. The implementation of robots is huge in the industry, since robots are generally not made for a specific purpose. Engineers like me figure out how to implement a robot for my company and for the products we make.

One piece of advice I’d give is:

“Sometimes, knowing what you don’t want to do for a career is just as important as knowing what you do want to do. It helps to “prune the tree” a little bit.”

Even now in my career, I still don’t 100% know what I want to do. However, I’ve been able to start “pruning the tree” to eventually find the right path for me. By eliminating options, I can keep exploring what I still like and take opportunities that come up in those areas to see what I like best.

Read more ‘Day in the Life’ articles:

- A Day in the Life of a Computer Engineer Angela Lo

- A Day in the Life of Environmental Engineer Renata Spinosa

- A Day in the Life of An Aerospace Engineer

- A Day in the Life of Chemical Engineer Rosa Rueda, Ph.D.

Author

-

SWE Blog provides up-to-date information and news about the Society and how our members are making a difference every day. You’ll find stories about SWE members, engineering, technology, and other STEM-related topics.