Sowmya Nagesh

I got into engineering because I liked solving problems. My father was an electrical engineer, and he was the first engineer in my extended family. I was the second one. Growing up, I liked watching him work with circuits. I liked the way we could read signals, measure electrical properties like current, voltage, power, and conductivity, and decode the data. As I got into the later years of high school, I also liked decoding data into zeros and ones, then piecing the data together, which is what most electrical engineers do. I was especially excited when I could read the meter in my house, notice how it went up and down seasonally, and understand how it translates to what electrically happens in the lines behind the walls of my home. I ended up going into electrical engineering because it is so fundamental and necessary for knowing how things are made to work in everything that we use in the world around us.

I first received my Bachelor’s degree in Electrical and Computer Engineering from Visvesvaraya Technological University then received my Master’s degree in Electrical and Computer Engineering from the University of Illinois at Chicago. While I was an undergraduate student, I worked as a Project Intern for six months in the sensors department at the Indian Space Research Organization. I worked on writing sensor controls for satellites. This was my first exposure to working with any real-life application, since I could see that the accelerometer controls that I wrote were going to be used in space. This also gave me my first exposure to embedded systems. Embedded systems are systems that go into a controller in any application that involves electronics. These different controllers talk to each other to make the machine operate correctly. Any appliance or anything that has electronics in them, these days, has embedded systems. Usually, the code that is written for these systems uses a language called C or a tool called MATLAB that allows you to build blocks of code. This internship experience helped me with my first job at Caterpillar, Inc. after graduate school, where I worked in embedded systems from the get-go. I started working with engine controls and from there on, I progressively worked in different spaces in controls engineering. This involves a mix of designing both hardware and software that go into machines.

I recently started a new job as an Engineering Project Team Lead at Caterpillar, Inc. where I have been working at the cutting-edge of alternate power systems. I work on new technology for new sustainable power systems that will go in the machines, locomotives, and stationary power systems of tomorrow. I use every single aspect of what I learned in my undergraduate and graduate education, such as my electrical circuit classes. These classes have come in handy when I am troubleshooting issues that arise when I am putting together all of these complex power systems. My work makes sustainable sources happen, which is the best part about my job.

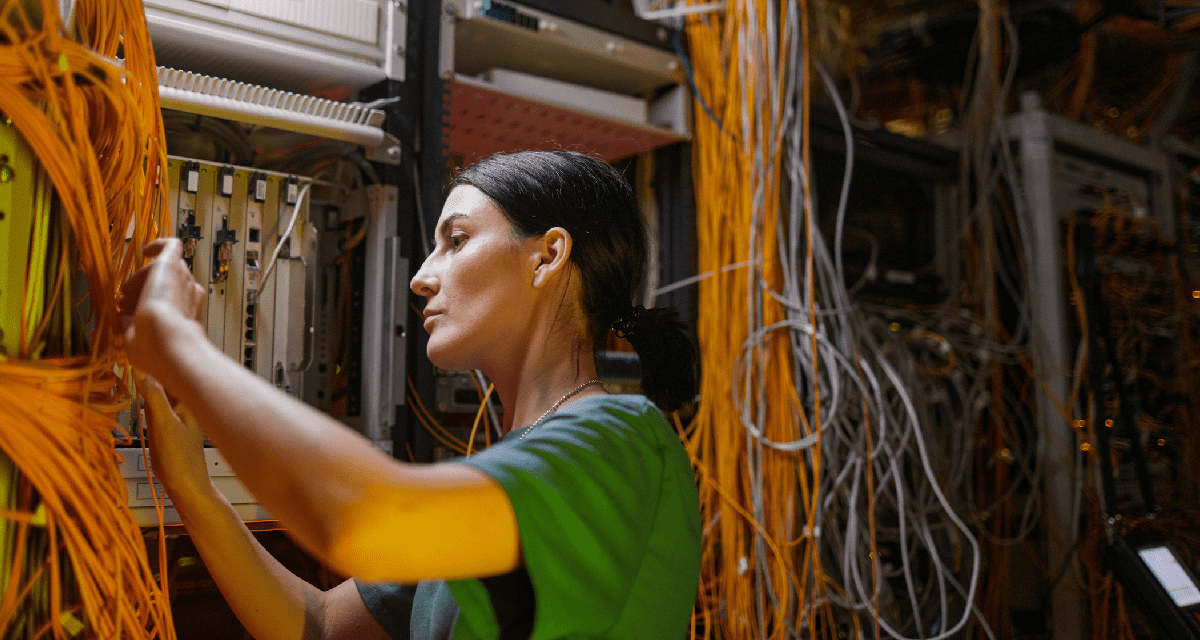

One of my favorite projects at work was when I created a hardware lab where everything was automated. I had to control how many times I would have to run an iteration of code to control certain machines. Multiple ways to operate the machine were controlled on a complex lab interface where I could switch through different applications. I had to figure out how to run different iterations remotely if I had to test a new feature that was being developed. I was able to run these tests from home multiple times to make sure that the little computers, or electronic control modules (ECMs), worked as effective controllers. I had to make sure that they could handle the workload and amount of communication in continuous loops. This was one of the coolest projects I worked on because I had to use a lot of my knowledge of making and building electronic circuits and my skills in coding. I also had to be very hands-on because I built the harnesses myself, soldered breadboards and switching circuits by hand, and tinkered around with so many different components. This was a very interesting and challenging experience for me. We are still using the lab setup I created six years ago.

To girls interested in Electrical Engineering, don’t be afraid of snipping, crimping, or splicing circuits and wires. Try to get a solder gun, multimeter, or breadboard and start playing around with electronics, such as Christmas lights, or Diwali lights, or Hanukkah lights, or ornaments from whatever you are celebrating. Don’t be afraid to put together or take apart things. You can read a multimeter in different modes and ask why the part you’re testing is designed that way. I did not have access to a lot of these things growing up in India, but I do a lot of local outreach and this is what I encourage my mentees to do. Electrical engineers are essential now more than ever, especially since we are looking into alternate sources of new, carbon-free energy. I would encourage students to look into these experiences and not be afraid of taking apart things and putting them back together

Author

-

Kristine Loh (she/her) is a PhD Candidate in Chemical Engineering at the University of Minnesota. As an NSF Graduate Research Fellow in the Ferry and Kortshagen Groups, she studies the optical properties of nontoxic nanomaterials for their applications in renewable energy technologies, such as solar windows and greenhouse roofs. Outside of research, she enjoys K-12 STEM outreach, experimenting with her air fryer, and trying new restaurants in the Twin Cities.