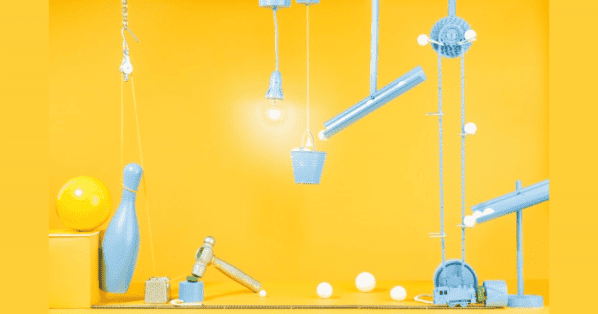

This month, we’re challenging you to think like a Mining Engineer by extracting valuable minerals from the ‘ore’ containing the mineral. Some minerals in a sample of ore contain elements of interest, while other minerals are merely part of the rock. The minerals of interest need to be concentrated, usually by mechanical or chemical means.

Materials:

- 1 cup each of iron-fortified cold cereal (Total works great)

- 2 cups water

- 1 clear drinking glass

- White magnet stirring bar or Popsicle stick with magnet strip glued to one side then painted with white epoxy paint. Needs to be light colored to allow you to see the minerals.

- Kitchen scale

- Paper towel

Procedure:

Cold cereals are fortified with vitamins and minerals for health. Metallic iron is added to fortified cereal, and this form of iron is magnetic. In this experiment we will use the magnetic properties of the iron to extract it from the cereal. In other processing methods for nonmagnetic metals (such as copper, uranium, and gold), acidic or caustic water, gravity separation, or flotation might be used to separate the element of interest from the waste rock.

- Select a sample of cereal that is iron-fortified such as Total. Weigh it and note the weight below:

SAMPLE 1: ______________

SAMPLE 2: ______________

SAMPLE 3: ______________

- Add hot water to SAMPLE 1 to make a slurry, stirring with the magnet until the cereal is soggy- about 1 minute. Remove the magnetic stirrer and note the dark slivers of iron on the ends of the magnet. These are particles of metallic iron.

- Recover the iron particles by depositing/wiping them onto the paper towel and save for later.

- Add cold water to SAMPLE 2 to make a slurry, stirring with the magnet until the cereal is soggy. Recover iron particles onto a second paper towel.

- Add hot water to SAMPLE 3 to make a slurry, rather than stir use the magnet to mash the cereal and pulverize to make a thinner slurry than previously. Recover iron particles onto a third paper towel.

- Dry the iron by letting the iron sit over night, or heating the sample in a warm oven then weigh the sample to determine the fraction of iron in the cereal.

SAMPLE 1: ______________

SAMPLE 2: ______________

SAMPLE 3: ______________

- Calculate the percentage of iron by weight in the cereal by dividing the weight or iron by the total weight of the sample. How does this compare to what the cereal box says was added?

SAMPLE 1: ______________

SAMPLE 2: ______________

SAMPLE 3: ______________

- What effect does stirring have on separating the iron? Is stirring necessary? Is more iron recovered with longer stirring/mashing the sample?

- What effect did the temperature of the water have on separating the iron?

- Do you think adding more water (or less water) would change the outcome?

The crushing of the cereal models the crushing of the ore rocks to make the grains that contain the element of interest (in this case iron) accessible to the processing solution (water). Similarly, the stirring makes new parts of the ore accessible for processing.

Related content:

- SWEet Wisdom: How Important is Adaptability in STEM?

- Words of Wisdom for the Next Generation of Black Engineers

- Podcast: TIME‘s 2020 Kid of the Year, Gitanjali Rao

- SWEet Wisdom: How Can a Student Mentor Other Women In STEM?

- ‘Emily the Engineer’ Stuns TikTok with Marvelous Real-Life Iron Man suit

Author

-

SWE Blog provides up-to-date information and news about the Society and how our members are making a difference every day. You’ll find stories about SWE members, engineering, technology, and other STEM-related topics.