Stephanie DeCotiis is a project manager for H2M Architects and Engineers for the Water Resources department. She manages projects for drinking water treatment, storage, and distribution; supervises a group of staff and project engineers; and manages multi-discipline projects though conceptualization, design, permitting, and construction. As if that weren’t enough, she decided to add some more (unpaid) work to her plate: making personal protective equipment (PPE) for frontline workers at hospitals around the U.S.

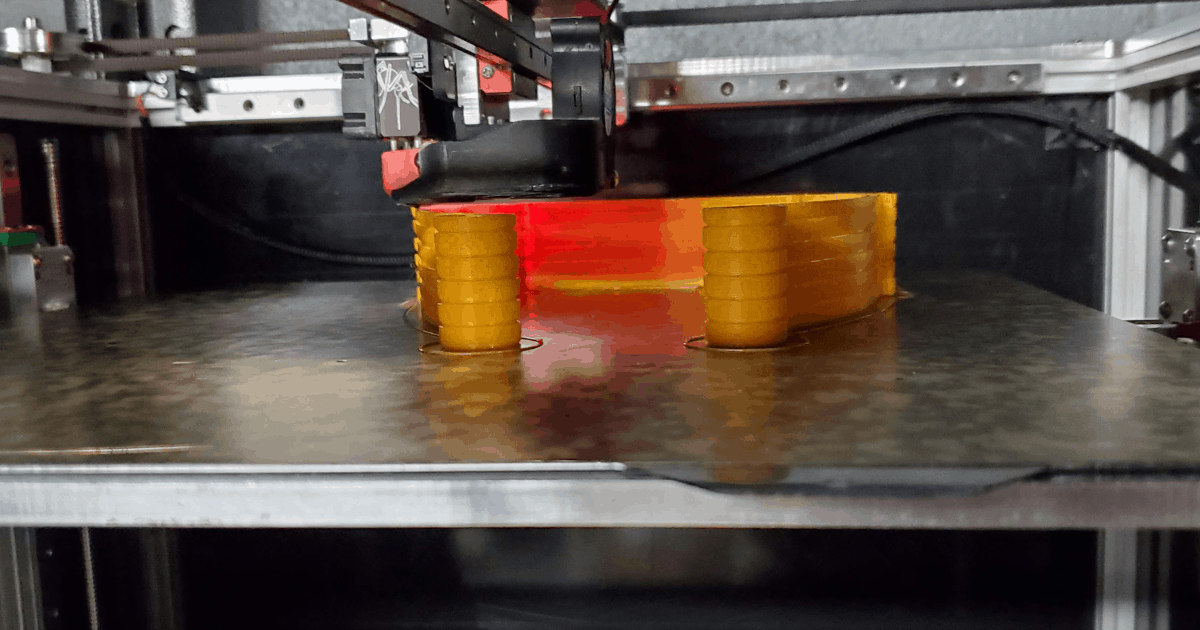

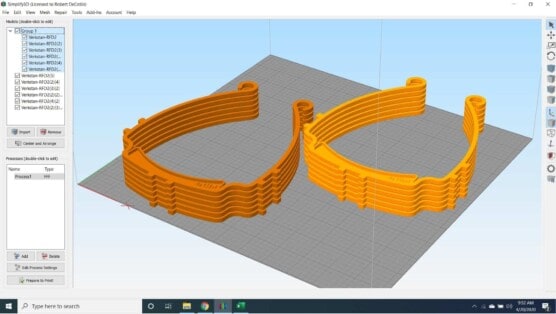

When the pandemic first started, DeCotiis and her husband realized that PPE was in very short supply for health care workers, particularly in the hard-hit New Jersey/New York area, where they live. Wondering if they might possibly help create PPE from their basement 3D printers, they did some research and found that there were several 3D printable templates for face shields available. At that point, they started sourcing material and printing them for friends and family who work as nurses and doctors.

Finding a network to strengthen efforts

Once DeCotiis and her husband had stabilized their production, they went looking for a network they could connect with to help distribute their shields to a greater audience, and they found the SOMA NJ 3D Printers Alliance—a group of volunteers with a more organized structure to process donation requests and funding. DeCotiis and her husband joined the group in mid-April 2020, their added printing capacity helping the group meet the demands for PPE requests.

But while the SOMA Alliance has donated thousands of masks, they certainly weren’t free. Fortunately, generous donations received through SOMA Alliance’s Go Fund Me page completely covered the cost of materials. For reference, each 1kg roll of plastic filament can produce approximately 55 face shield frames, and costs about $20-$25 per roll. Each shield also needs to be fitted with the clear film material, which runs about $20 for 100 sheets. All in, each shield costs approximately $1 to produce and deliver.

Where SOMA first focused their efforts on providing PPE to front line workers (nurses, doctors, EMTs, nursing homes, etc.), they are now donating shields to other medical offices (dentists, dermatologists, etc.) as well as to some needy school systems—most notably, SOMA sent several thousand pieces of PPE to the Navajo Nation school district in Arizona. DeCotiis and her husband have made over 3,000 shields, and the SOMA team has delivered around 48,000 shields to over 40 hospitals and other organizations.

Finding gratification—and frustration—throughout the process

For DeCotiis, the most gratifying moment was getting a text message from the Vice Chair of Internal Medicine at her local hospital telling her that SOMA’s shields were being used by his medical residents in the COVID ICU, and that their donations were making a huge difference in their safety. “It was both a proud and heartbreaking moment to know that the PPE I made in my basement was being used on the front lines,” said DeCotiis.

DeCotiis admits there was also some frustration along the way. “3D printers are temperamental precision machines that require tuning, programming, a deep understanding of how the code is being executed, and knowing what to change in order to improve the printed parts. We spent countless hours doing trial and error adjustments to speed up the production process in order to push out as many shields as possible per day.” At the height of the pandemic and their production, she and her husband were able to produce about 100-120 shields a day.

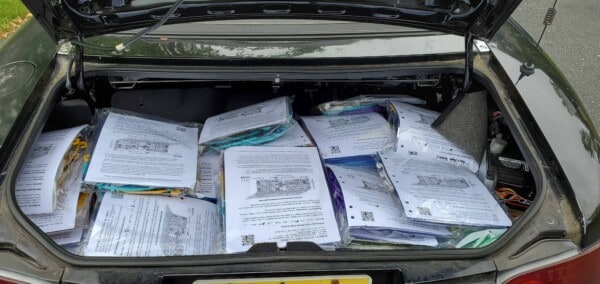

At this point, most of the supply chains have caught up, and 3D printing is no longer needed to fill the gap in PPE supply. It was an exhausting and rewarding experience that DeCotiis hopes they never have to do again—but they are ready for the second wave. “As a team, we ordered extra material and stored it at key printer’s homes around the state so that if/when numbers begin to climb and our hospitals are in need again, the SOMA 3D Printers Alliance will be ready, materials in hand, to fire up our printers at a moment’s notice.”

Related content:

- SWE Survey Report: Impact of COVID-19 on Women in Engineering and Technology

- Am I Doing Enough- Imposter Syndrome During COVID-19

- COVID-19: STEM Strikes Back

- From Congressional Visits to the “New Normal” Brought by COVID-19

- Section Highlight: See How SWE Boston Is Engaging Members During COVID-19

Author

-

SWE Blog provides up-to-date information and news about the Society and how our members are making a difference every day. You’ll find stories about SWE members, engineering, technology, and other STEM-related topics.